SPEEDY BUILDING

FOR PROFESSIONALS

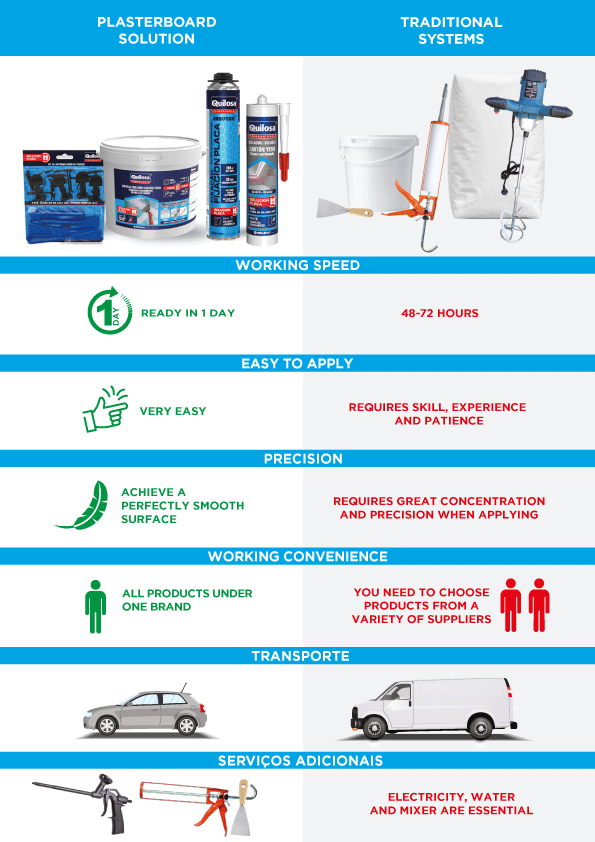

- FAST: up to 100m² in 1 hour.

- EASY: dust, water and electricity-free. Product ready to use.

- PRECISE: Automatic levelling of boards

See how fast you can fit it.

Main Advantages:

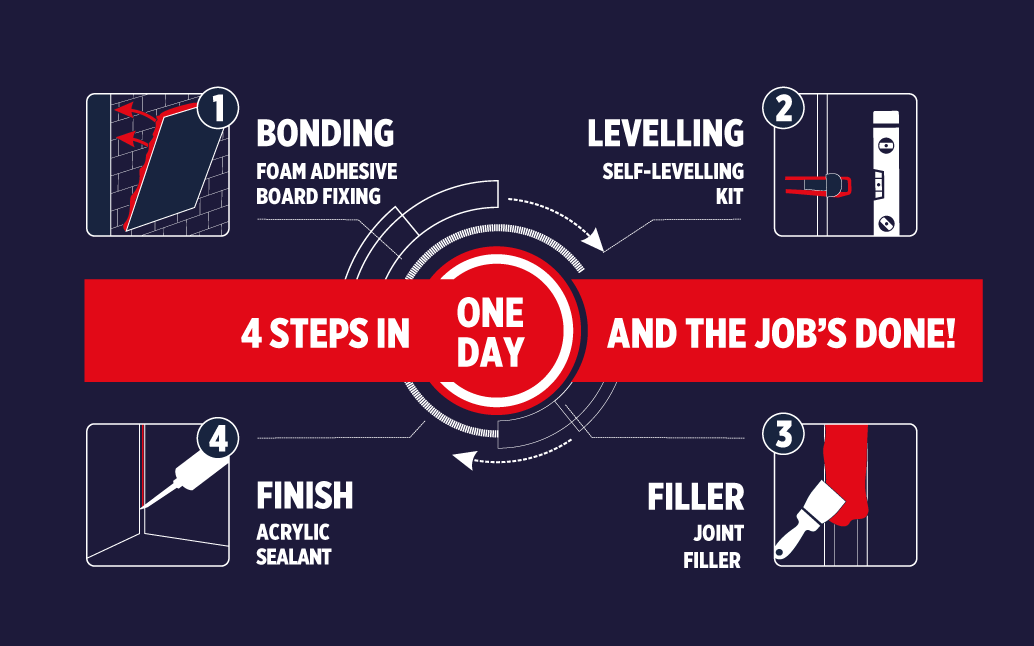

A comprehensive solution which is ready to use in 4 easy steps.

-

Fast fitting, up to 100m2 per hour

-

Self-levelling kit for boards to make the job easy. Perfectly level surfaces, even when working alone

-

Joined, plastered and finished in 30 minutes following bonding

-

Products READY TO USE. No preparation required

VERSATILE / MULTIMATERIAL

Check out the possible surfaces on which you can use our PLASTERBOARD SOLUTION!Improve the efficiency of your work

With a fast, easy, clean solution.

Forget about dirt and dust, shifting heavy bags, time-consuming mixtures that need water and electricity.

Are you looking for an efficient plasterboard fitting system? Do you feel that no solution has fully met your needs to date? Or perhaps you like to try novel solutions that will improve the quality of your work and save you time?

Go for this modern, comprehensive solution, which will not only make your work easier, but will also take up to 3 times less to do.

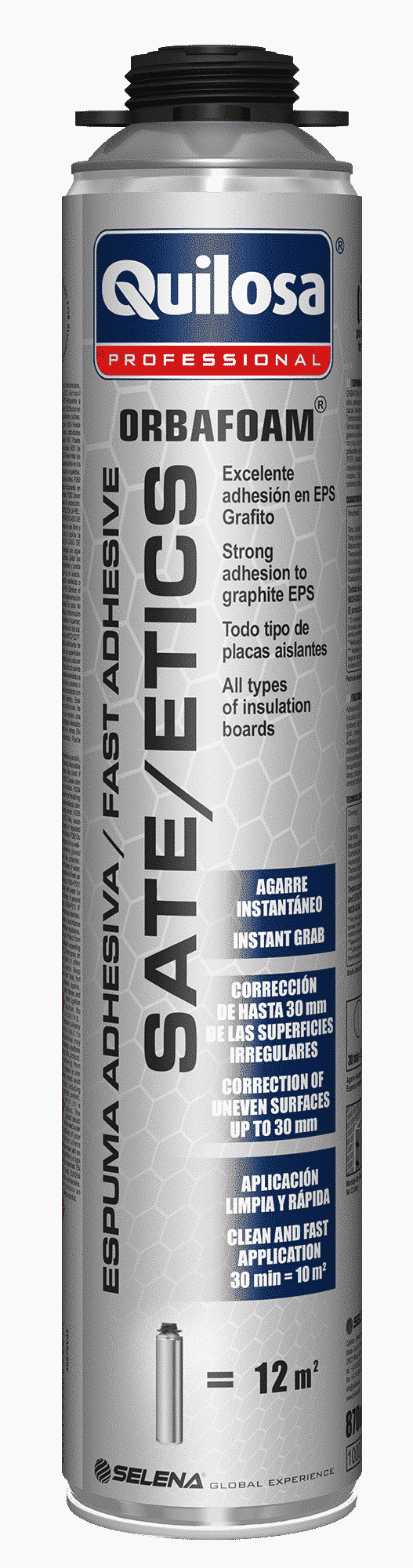

1. BONDING

PLASTERBOARD FOAM BONDING ADHESIVE

The first step in the plasterboard installation process is to bond the board to the surface. Traditionally, for this purpose, plasterboard adhesive cements are used, which have to be mixed with water using an electric mixer. Subsequently, the adhesive cement should normally dry for 24 to 72 hours before moving on to the next steps: filling or painting.PLASTERBOARD SOLUTION is the alternative to traditional bonding solutions:

-

Extremely fast

The curing time is only 2 hours compared to an average of 2 days for traditional adhesive cement.

-

Super performance

1 canister is the equivalent of 40 kg of adhesive cement.

-

Initial bonding

Save time and optimise your work during plasterboard installation.

-

High performance

With one box you can fit up to 10 m² of board, in other words, 3 standard boards.

-

Correction of uneven surfaces of up to 20 mm

It allows the correction of uneven surfaces of up to 20 mm.

-

Ready to use

The product is ready to use; there is no need for water or electricity to prepare it.

-

No post-expansion

Provides firm, easy bonding.

-

Fire resistance

Boards bonded with PLASTERBOARD ADHESIVE achieve reaction to fire class B-s1; d0 (PN-EN 13501-1:2008).

Technical specifications

| Colour: | Blue-green |

|---|---|

| Application temperature: | From +5°C to +30°C |

| Canister temperature: | From +10°C to +30°C |

| Application time (application to board): | ≤ 2 min. * |

| Working time: | ≤ 1,5 min * |

| Adjustment time: | ≤ 5 min* |

| Pre-curing time: | ≥ 30min* |

| Performance: | Up to 10 m² (3 standard boards)** |

| Fire resistance: | B-s1; d0 (PN-EN 13501-1:2008) |

| Cleaning: (only with solvents prior to curing): | Polyurethane foam cleaner (Orbafoam Quilosa Professional) |

2. LEVELLING

BOARD SELF-LEVELLING KIT

Patented system consisting of clips and wedges, which support and facilitate the work of BOARD FITTING by automatically aligning the boards with each other. You are probably familiar with the problems and difficulties associated with plasterboard installation. A small room, large boards, and on top of that... you are working alone. You bond the board to the wall, and then the biggest challenge begins: getting the perfect distance between the boards and aligning them as precisely as possible with each other.

-

PRECISION

The thickness of the positioner provides the correct joint.

The use of the self-levelling kit guarantees a uniform joint of 2-3 mm along the entire board joint. -

SPEED

Levelling of 2 boards in under 2 minutes

Use of the board self-levelling kit will significantly speed up your work, even when working alone! -

EASE

It is simple: just click and go to it. Done!

3 positioners and 3 wedges are enough to create a perfectly uniform joint between two standard boards. -

VERSATILITY

The kit is designed for boards of various sizes and thicknesses.

The kit contains clips and wedges of a shape suitable for use with a variety of board size on several planes.

3. FILLER

PLASTERBOARD FILLER

PLASTERBOARD SOLUTION includes a latest-generation ready to use filler. Ideal for joining boards. Reinforced with fibrillated fibres. The product has the consistency of a white paste. Thanks to its unique formula, it enjoys high technical and functional properties.It features high flexibility and strength, guaranteeing the durability of joints. It provides an optimum end result: perfectly smooth walls and ceilings.

-

SOLID AND LONG-LASTING

Using the plasterboard installation kit provides the ideal distance of 2-3 mm between the edges of two boards. This gap is ideal for PLASTERBOARD FILLER; the joint will not crack after curing.

-

READY TO USE

No preparation or additional steps required.

-

PERFECT CONSISTENCY

The product has the consistency of white paste, which is perfect for application and the modelling of joints and seams.

Technical specifications

| Application temperature: | From +5°C to +30°C |

|---|---|

| Colour: | White |

| Layer thickness: | Up to 5 mm |

| Curing time (depending on the thickness of the applied layer and environmental conditions): | Approx. 1-2 hours for a layer of 1 mm |

| Performance: | Approx. 0.3 kg/m2 for a layer thickness of 1 mm |

| Fire resistance class | A2-s1,d0 |

4. FINISH

PLASTERBOARD JOINT SEALANT

Acrylic sealant specially designed for sealing corners and all joints between boards or other surfaces. No cracking, no shrinkage, and can be painted!

-

HIGH FLEXIBILITY

The joint does not crack and neutralises the natural stresses of plasterboard. It is twice as flexible as traditional acrylics.

-

NO CRACKING, NO SHRINKAGE

Due to low shrinkage during curing, it does not crack or collapse.

-

PAINTABLE

Once cured it can be painted.

Technical specifications

| Application temperature: | From +5°C to +30°C |

|---|---|

| Heat resistance (after curing): | From -20°C to +80°C |

| Colour: | White |

| Movement quality (ISO 9047): | 12.5%-15% |

| Contraction: | ~25% |

Opinions from professionals

-

A well-prepared adhesive

In my opinion it is a very well-prepared adhesive, as it is easy to use on site when fitting plasterboard, and it saves you a lot of time compared to adhesive mortar; a job well done by Quilosa in creating this solution.Ver más -

A very good product

We created a plasterboard wall on one bedroom wall. We used plasterboard adhesive for the first time and it provided an excellent, strong bond; a very good product.Ver más -

Practical and fast

Very practical and fast; its performance surprised me. I will never be without it when fitting.Ver más

See more fast and professional solutions

Solutions providing clear benefits for your work:- SPEED UP WORKING TIME

- PROVIDE MAXIMUM QUALITY

- INCREASE PROFITABILITY

-

ULTRA FAST 70

ULTRA FAST 70- Ready to cut in 10 min.

- High performance -> 70L

- Controlled expansion

-

SETS IN 60 SECONDS

SETS IN 60 SECONDS- 1 canister = 40m = 25kg mortar = 6 bonding adhesives

- Initial tack in 60 seconds

- Extreme strength

-

POWER FIX INSTANT STRONG

POWER FIX INSTANT STRONG- Immediate grip in 5 seconds

- Initial setting in 30 minutes

- Cured strength 400kg/10cm2

-

PERFECT BATHROOM

PERFECT BATHROOM- Dry in 15 minutes

- 15-year mould-free guarantee

- Odourless

- For all materials

-

-

AQUA PROTECT P4

AQUA PROTECT P4- Easy to apply

- Ready to use

- Completely set in 12 hours

- Applicable even on wet surfaces